Share

Side panel

Need to find the right solution, please contact our technicians,Contact us!

Classification

Label

- Product Description

-

1. Introduction

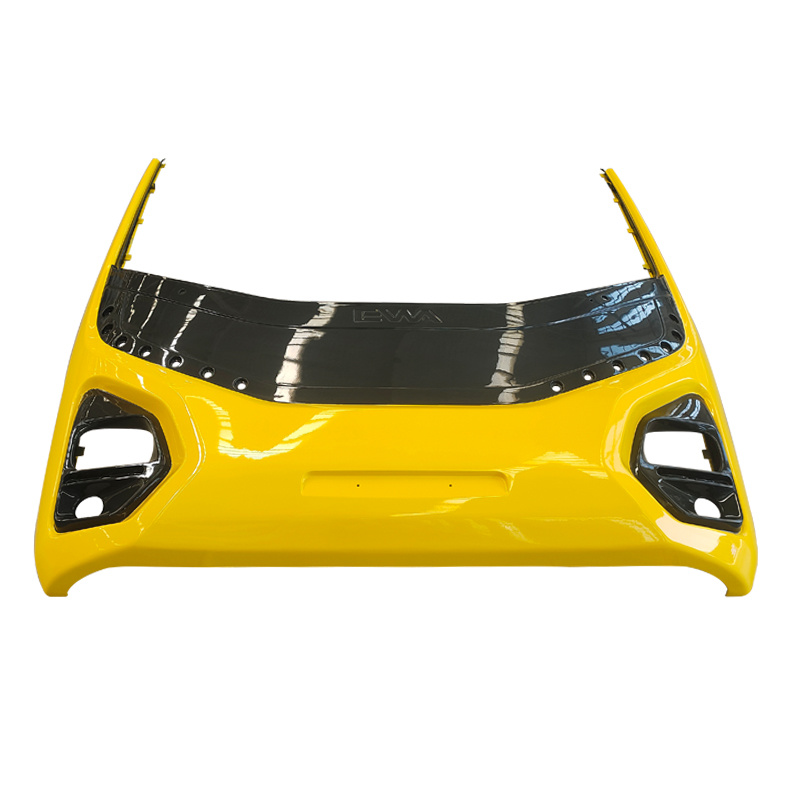

With the continuous progress of industrial technology, fiber-reinforced composites (FRP) are more and more widely used in various fields. In the fields of construction, transportation, aerospace and other fields, the products manufactured by FRP process are favored for their light weight, high strength and corrosion resistance. As an important part of many equipment and structures, side panels are manufactured by FRP process with significant advantages.

Brief Introduction of 2. FRP Process

FRP (fiber reinforced composites) process is a kind of glass fiber, carbon fiber and other reinforced materials combined with resin matrix, through a specific process to make high-performance composite materials. Its main raw materials include resin, reinforcing fiber, filler, etc., through mold molding, curing and other steps, and finally get the desired product.

Application of FRP Process in the Manufacture of 3. Side Panel

Side panels in many occasions, such as vehicles, buildings, ships, etc., need to have light weight, high strength, corrosion resistance and other characteristics. The FRP process is used to manufacture the side panel, which can meet these requirements.

1. Material selection: According to the use and required performance of the side panel, select the appropriate resin, reinforcing fiber and filler.

2. Mold design: According to the shape and size of the product, design the mold to ensure the accuracy of molding.

3. Molding: Pour the mixed material into the mold and shape it through a specific process.

4. Curing: curing the molded product to achieve the required strength and hardness.

5. post-treatment: after the curing of the product polishing, coating and other post-treatment, so that it can meet the final use requirements.

Advantages of 4. FRP side panels

1. Lightweight: The FRP material has a low density, and the side panels made are light in weight, reducing the burden on equipment and structure.

2. High strength: FRP material has high strength, good tensile and compressive properties.

3. Corrosion resistance: FRP material is corrosion resistant and suitable for various harsh environments.

4. Flexible design: side panels of various shapes and sizes can be designed according to requirements.

Environmental protection: FRP materials can be recycled and reused, which is conducive to environmental protection.

5. Conclusion

FRP technology has significant advantages in the manufacture of side panels. With the continuous progress of technology and the reduction of cost, FRP side panels will be applied in more fields. In the future, the FRP process will play a greater role in the manufacturing industry and promote industrial upgrading and green development.

Side panel

Need to find the right solution, please contact our technicians,Contact us!

Classification

Keywords

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Products