Main Equipment

01 Painting production equipment

The coating is an assembly line design, with a total of 8 dust-free grinding rooms, 2 dust-free spraying rooms and 1 baking room to ensure the stability of the product surface spraying quality;

02 Accumulated chain spraying line

Accumulation chain spraying line equipment, by the automation equipment to the product flow, reduce artificial transfer, increase spraying efficiency effectively reduce the process quality risk, to ensure the stability of the product surface spraying quality.

Accumulation chain spraying line

CNC machining center

Polyurethane foaming process equipment

Embedded parts processing equipment

Embedded parts processing equipment

Rotomolding machine

Stamping parts processing equipment

Stamping and molding equipment can independently complete various types of stamping parts. The embedded parts of various types and styles used in the products produced by our company can be completed by self-control, which can greatly reduce the production cost, effectively improve the process quality control, and play a good escort for the product quality.

Stamping parts processing equipment

Stamping parts processing equipment

SMC molding production equipment

The process of adding SMC sheet in the metal mold and curing the molded product at a certain temperature and pressure.

Its production efficiency, high dimensional accuracy, smooth surface, no secondary modification. Products with complex structure can be formed at one time.

It is suitable for the production of vehicle parts, engineering vehicle parts, and exterior parts with high size requirements.

At present, there are 500T, 1500T, 2500T, 4000T and other different types of hydraulic presses, which can meet the pressing of products of different shapes and sizes;

SMC molding production equipment

SMC molding production equipment

SMC molding production equipment

SMC molding production equipment

Injection molding equipment

Its process products have the characteristics of surface quality, high dimensional accuracy, long service life, light weight and high production efficiency.

Suitable for a variety of automotive interior and exterior parts and products with high size requirements. At present, there are 8 injection molding machines of different types, including 320T to 2600T and other different models. The maximum injectable weight can reach 20Kg, and the production capacity is stable and reliable.

Injection molding equipment

Injection molding equipment

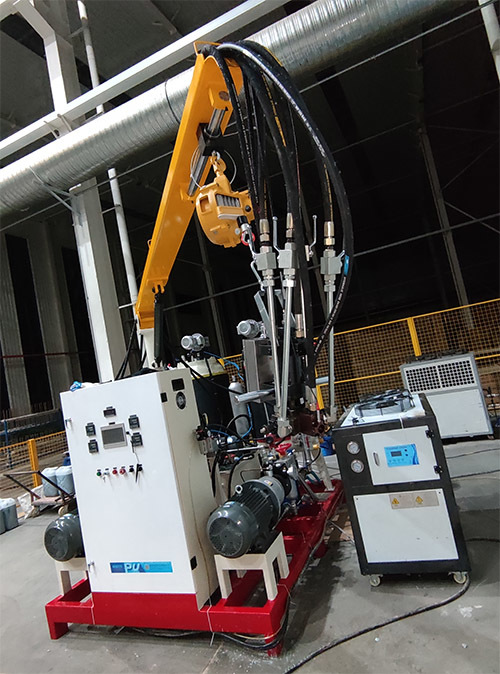

PDCPD process molding equipment

The DCPD resin A, B material, under pressure into the mixing head, injection, polymerization molding of a process.

The process has high-quality product performance and environmental protection. As a new type of high impact material, polydicyclopentadiene (PDCPD) not only has high impact strength, high bending modulus, excellent corrosion resistance and low density, but also is easy to form, does not require high temperature and high pressure, and saves energy.

PDCPD process molding equipment

PDCPD process molding equipment

PDCPD process molding equipment

Molding vulcanization process molding equipment

The equipment is mainly used for the production of rubber products, the rubber raw materials under high temperature and high pressure vulcanization, the vulcanized rubber material is squeezed into the insert or mold cavity to shape into rubber products;

Common ones include various rubber strips, automobile tires, car rubber sleeves, etc. At present, our company has 16 molding and vulcanizing equipment.

Molding vulcanization process molding equipment

Molding vulcanization process molding equipment

Molding vulcanization process molding equipment

Acelie five Angle color difference meter

Cantilever beam impact testing machine

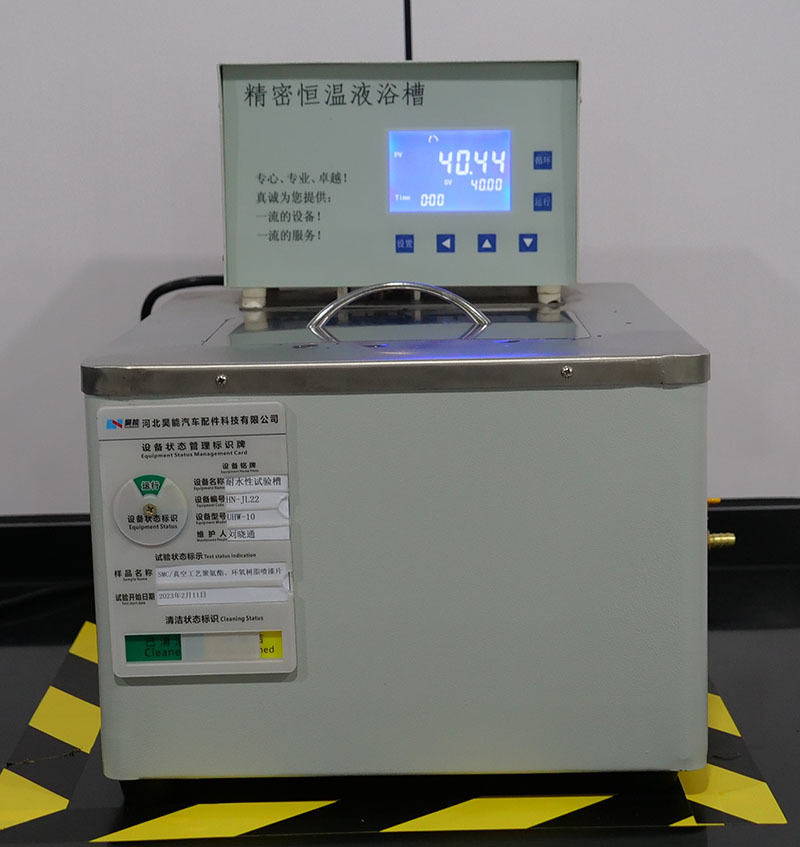

Water resistance testing machine

High and low temperature testing machine

Portable digital display tension instrument

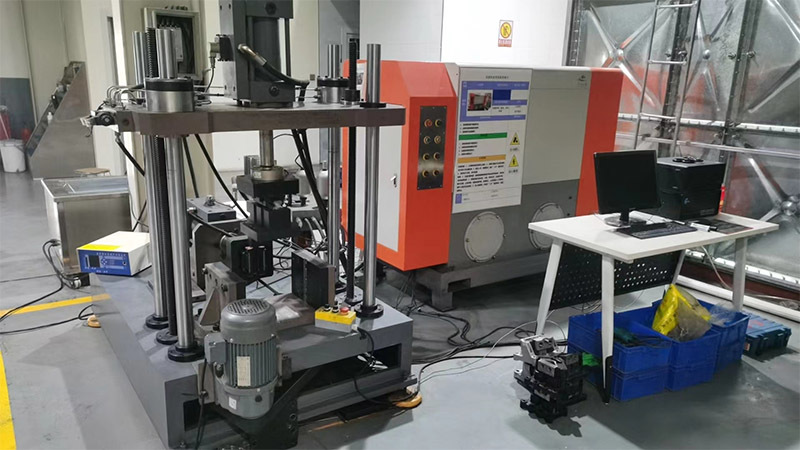

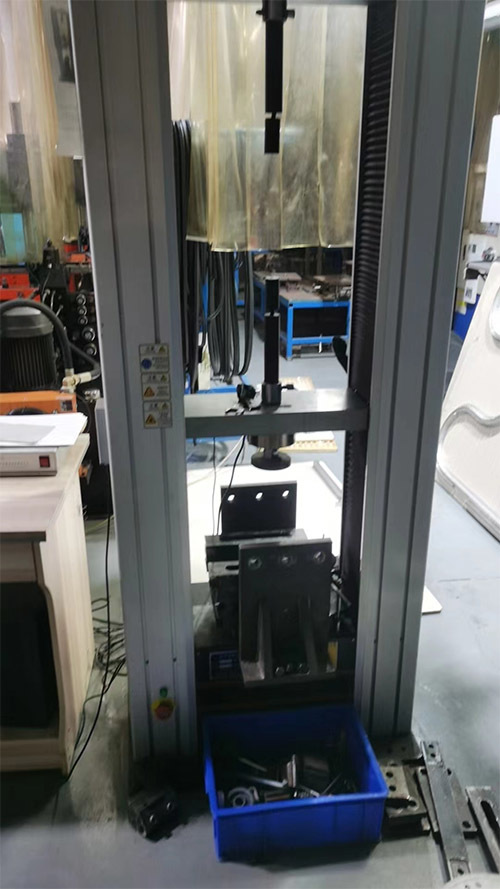

Static and dynamic stiffness testing machine

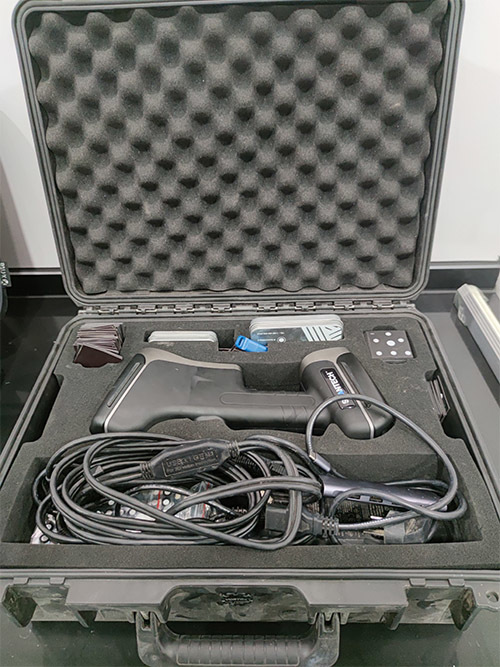

Method such as joint arm coordinate

Ultrasonic paint film thickness gauge