Share

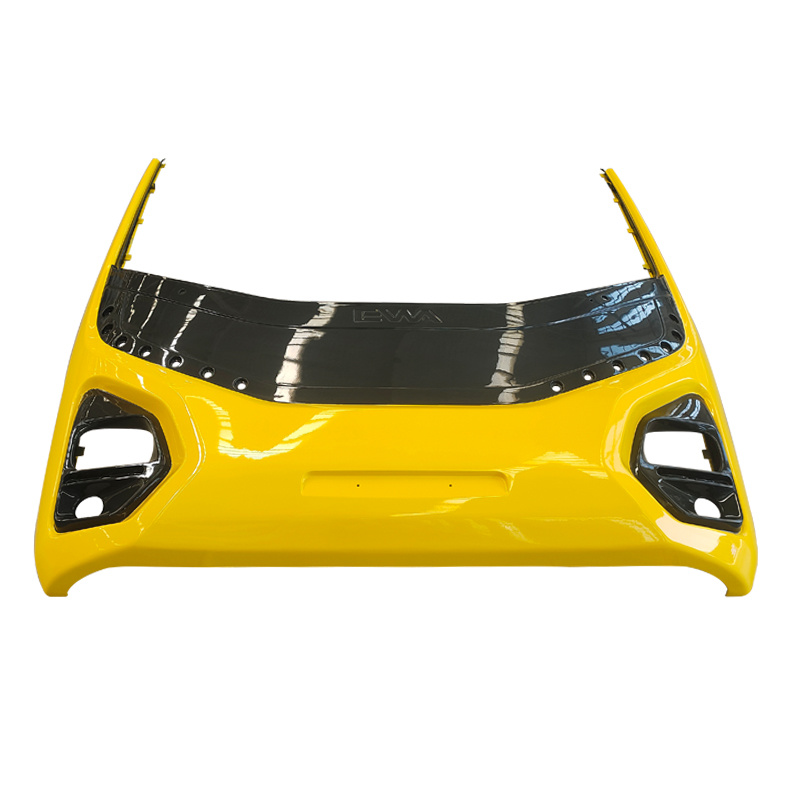

Front lower wall

Need to find the right solution, please contact our technicians,Contact us!

Classification

Label

- Product Description

-

SMC process, that is, sheet molding composite process, is an advanced composite molding technology. This process has significant advantages in the manufacture of automotive parts such as front and lower circumferences. The following is a brief introduction to the application of the SMC process in the manufacture of the front lower wall.

1. process principle

The SMC process is a process in which a fiber-reinforced material is mixed with a resin to make a sheet-like prepreg, which is then molded by a molding device at high temperature and high pressure. Its principle is simple, easy to operate, suitable for mass production.

Application of 2. Front and Lower Wai Manufacturing

1. Material preparation: Select appropriate fiber reinforced materials and resins, and mix them in a certain proportion to make SMC sheet prepreg.

2. Mold design: according to the shape and requirements of the front and lower circumference of the mold design, the mold should have excellent high temperature resistance, corrosion resistance.

3. Molding process: Put the SMC prepreg into the mold, and apply high temperature and high pressure through the molding equipment to form the material in the mold.

4. Follow-up treatment: The front and lower walls after molding need to be post-treated, such as burr removal, polishing, painting, etc., to meet the final product requirements.

3. Advantage

1. High production efficiency: SMC process can realize automatic production, greatly improving production efficiency.

2. Product quality and stability: SMC process of forming the front of the lower circumference of accurate size, high surface finish, stable quality.

3. Lightweight: SMC material has excellent lightweight performance, which can effectively reduce the weight of the whole vehicle.

4. Environmental protection: SMC materials can be recycled, which is conducive to environmental protection.

4. considerations

1. Strictly control the material ratio: ensure that the mixing ratio of fiber reinforced material and resin is accurate to ensure the performance of the product.

2. Mold maintenance: Mold maintenance and maintenance are very important to product quality and should be checked and maintained regularly.

3. Operating specifications: Operators need to strictly abide by process specifications to ensure product quality and production safety.

In short, the SMC process has significant advantages in front and lower wall manufacturing, which can improve production efficiency, reduce production costs, and ensure product quality. With the continuous development of the automotive industry, SMC process will be applied in more fields.

Front lower wall

Need to find the right solution, please contact our technicians,Contact us!

Classification

Keywords

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Products