Share

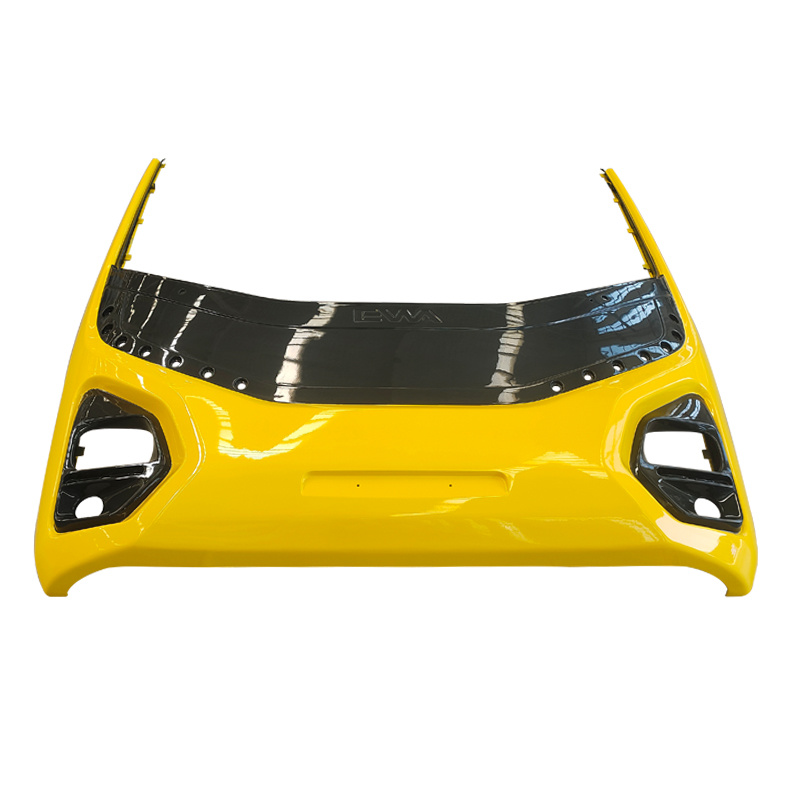

Bumper

Need to find the right solution, please contact our technicians,Contact us!

Classification

Label

- Product Description

-

1. Introduction

With the rapid development of the automobile industry, the performance requirements of auto parts are also increasing. As an important safety component of a car, the choice of its manufacturing process is directly related to the performance and safety of the car. SMC(Sheet Molding Compound) process is an advanced mold forming technology, which is widely used in the production of automobile bumpers and other parts.

2. SMC Process Overview

SMC process is a kind of glass fiber, filler, resin and other raw materials after mixing, stirring, and then through the mold hot pressing molding of a process method. It is characterized by accurate product size, high surface finish and excellent mechanical properties.

3. SMC bumper manufacturing process

1. raw material preparation: select suitable glass fiber, filler and resin, according to a certain proportion of mixing.

2. Mold design: According to the shape and performance requirements of the bumper, design a suitable mold.

3. Raw material pressing: Put the mixed raw materials into the mold and press them by a hot press.

4. Curing and post-treatment: After a period of curing, demoulding to obtain a preliminary bumper product, and then post-treatment, such as polishing, painting, etc.

Advantages of 4. SMC bumpers

1. Excellent performance: The bumper manufactured by SMC process has the characteristics of high strength, high rigidity and good impact resistance.

2. Lightweight: Compared with traditional metal bumpers, SMC bumpers are lighter, which helps reduce the weight of the vehicle and improve fuel economy.

3. Environmental protection: SMC materials can be recycled, which is conducive to environmental protection.

4. Cost control: SMC process has high production efficiency, which helps to reduce production costs.

5. challenges and prospects

Although the SMC process has many advantages in bumper manufacturing, it also faces challenges such as high cost and strict technical requirements. With the continuous advancement of technology and cost reduction, the application prospect of SMC process in automobile bumper manufacturing will be broader.

6. Conclusion

The application of SMC process in bumper manufacturing has brought many advantages to the automotive industry. With the continuous development and progress of technology, SMC process will play a greater role in the field of automobile bumper manufacturing.

Bumper

Need to find the right solution, please contact our technicians,Contact us!

Classification

Keywords

Product inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Related Products